Exploring the Essential Role of Metalworking Oil in Enhancing Precision and Efficiency in Industrial Applications

Metalworking oil is an unsung hero in the industrial world, playing a pivotal role in ensuring precision and efficiency across a wide range of manufacturing processes. From automotive to aerospace, the quality of metal components often hinges on the performance of these specialized lubricants. As industries continue to push the boundaries of technology and demand higher standards, the importance of metalworking oil cannot be overstated. This article delves into the critical functions of metalworking oil, exploring how it enhances operational efficiency, extends tool life, and ensures the highest levels of precision in industrial applications.

The Lubrication and Cooling Properties of Metalworking Oil

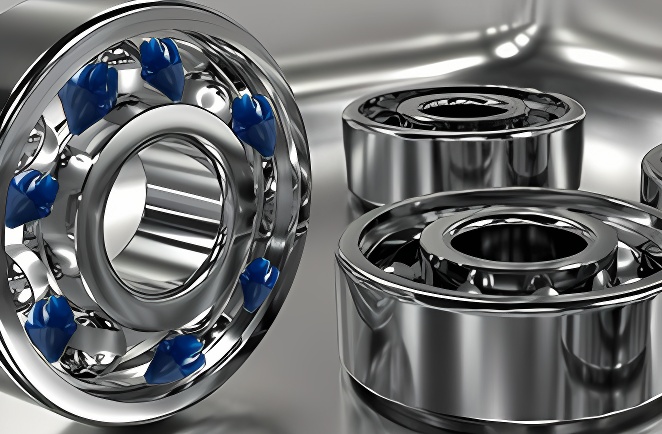

One of the primary functions of metalworking oil is to reduce friction between the cutting tool and the workpiece. Friction generates heat, which can lead to tool wear and dimensional inaccuracies in the finished product. By providing a protective layer, metalworking oil minimizes direct contact, thereby reducing heat generation and ensuring smoother operations.

In addition to lubrication, these oils also serve as effective coolants. High-speed machining processes can produce extreme temperatures, which may compromise the integrity of both the tool and the material. Metalworking oils dissipate heat efficiently, maintaining optimal working conditions and preventing thermal deformation. This dual role of lubrication and cooling is essential for achieving high precision and prolonging equipment life.

Enhancing Tool Longevity and Performance

Tool wear is a significant concern in metalworking, as it directly impacts both cost and quality. Metalworking oils form a protective barrier that reduces abrasive wear and prevents the adhesion of metal particles to the tool surface. This not only extends the lifespan of cutting tools but also maintains their sharpness, ensuring consistent performance over time.

Moreover, advanced formulations of metalworking oils contain additives that combat corrosion and oxidation. These additives protect tools and machinery from environmental factors, further enhancing durability. By reducing the frequency of tool replacements, industries can achieve substantial cost savings and minimize downtime.

Improving Surface Finish and Dimensional Accuracy

The quality of the surface finish is a critical metric in many industrial applications. Metalworking oils contribute to smoother finishes by reducing friction and preventing the buildup of debris on the workpiece. This is particularly important in industries like aerospace and medical devices, where even minor imperfections can have serious consequences.

Dimensional accuracy is another area where metalworking oils excel. By maintaining stable temperatures and reducing tool deflection, these oils help ensure that components are manufactured to exact specifications. This level of precision is indispensable for industries that require tight tolerances and high-quality standards.

Environmental and Safety Considerations

While metalworking oils offer numerous benefits, their use also raises environmental and safety concerns. Modern formulations are increasingly designed to be biodegradable and free from harmful chemicals, aligning with global sustainability goals. These eco-friendly options reduce the environmental footprint without compromising performance.

Safety is another critical aspect, as exposure to metalworking oils can pose health risks to workers. Innovations in low-mist and non-toxic formulations have significantly improved workplace safety. Proper handling and disposal practices are also essential to mitigate risks and ensure compliance with regulatory standards.

Future Trends and Innovations

The future of metalworking oils lies in continuous innovation. Researchers are exploring nano-additives and synthetic base oils to enhance performance further. These advancements promise even greater efficiency, precision, and environmental sustainability.

Additionally, the integration of smart technologies, such as sensors to monitor oil condition in real-time, is revolutionizing maintenance practices. Predictive analytics can optimize oil usage, reducing waste and improving operational efficiency. As industries evolve, metalworking oils will remain a cornerstone of precision manufacturing.

SUBSCRIBE

INQUIRY